Flexitallic GmbH

Gasket Manufacture

And Application Consulting –

Willich, Germany

Flexitallic GmbH

Gasket Manufacture

And Application Consulting –

Willich, Germany

About Us

Part of the Flexitallic Group, the Flexitallic GmbH Service Centre and warehouse operates out of Willich, Germany and offers Specialist Sealing Solutions, Application Consulting and Engineering Services, to meet the bespoke gasket and seal requirements of customers across Germany and Europe.

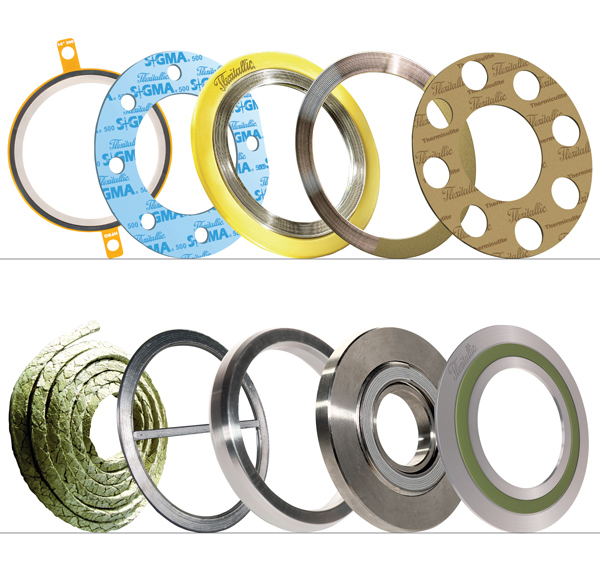

Manufacturing capabilities at Flexitallic GmbH include Spiral Wound Gaskets, Kammprofile Gaskets and Flat Gaskets, along with large stocks of finished goods and in-house gasket cutting facilities.

Products – Overview

Flexitallic remains at the forefront of developing sealing solutions for industries across the world. Flexitallic GmbH offers a wide range of high quality standard gaskets and specialist/customised sealing solutions that allow customers to operate their plants, complete projects and start up from shutdowns safely and efficiently. These products include:

- Spiral Wound Gaskets

- Kammprofile Gaskets

- Sigma PTFE Gaskets (Sigma 500, 511, 533, 588, 600 ePTFE, 850 ePTFE)

- Gasket Sheets

- Flat Gaskets

- Fiber Seals/Gaskets

- Insulation Kits

- Packings

- Seals/gaskets for high pressure, high temperature applications

- Seals/gaskets for pumps valves

Thermiculite®

Process temperatures are rising and operators are looking to extend maintenance intervals. This requires gasket/sealing materials suitable for high temperature applications up to 1000°C which offer safe, long term reliability.

To address these issues, Flexitallic developed a material which has the same gasket sealing characteristics of graphite but the thermal resistance of mica – Thermiculite® high temperature gasket materials.

Suitable for use in critical sealing applications, Thermiculite® has a proven track record in fertilizer, nitric acid, ethylene, reformer and ammonia production, and is available as a gasket sheet, spiral wound gasket, kammprofile gasket, Change™ gasket and valve stem packing.

- High temperature gaskets/seals

- Fire-safe gasket/seals (API 6FB)

- Seals for high temperature packings/valves

- Seals for Molten Salt applications

- Gasket materials for Fuel Cell SOFC

- Gasket/Seals for Fertilizer production

- Cryogenic gasket/seal applications

Change™ Gasket

Due to the cyclical nature of temperature ranges handled by shell and tube heat exchangers, Change™ was originally developed by Flexitallic as a heat exchanger gasket, in response to customers’ long-term sealing problems.

Proven to outperform all other gaskets, Change™ has high recovery properties, without comprising tightness, which is essential in high temperature, thermal cycle applications.

Other typical Change™ applications include boiler manhole gaskets, damaged flanges, reactor seals (FCC, coker, hydrogenation, ethylene/fertilizer production).

- Gasket/Seal for Heat Exchangers

- Fire-safe gasket/seals (API 6FB)

- Gasket/Seals for thermal expansion/thermal cycling

- Gasket/Seals for low surface pressure

- Gasket/Seals for renewable energy

Sigma® (PTFE)

Utilising a unique manufacturing process exclusive to Flexitallic, SIGMA® represents the latest generation of multidirectional PTFE materials, which offer very high chemical resistance in processes ranging from cryogenic temperatures to 260°C.

All SIGMA® materials and PTFE filled seals/gaskets are FDA compliant, making them ideal for use in industries where product contamination is of concern.

Sigma 500 blue – PTFE modified with hollow glass microspheres. Enhanced compressibility for low bolt loads. Designed for glass pipelines, plastic and thin or distorted metal flanges.

Sigma 511 fawn – PTFE modified with silica filler. Suitable for strong acids (except hydrofluoric) and general chemicals.

Sigma 533 white – PTFE modified with barium sulphate. Suitable for strong alkalis and other general chemicals.

Sigma 588 sandwich – PTFE material with low stress characteristics, ideal for low load sealing in damaged flange surfaces. Used in both concentrated acid and alkali service.

Sigma 600 white – PTFE material with low stress characteristics and high compressibility for ultra low bolt loads; plastic and glass lined equipment. Universal material suitable across a wide range of chemical media.

Sigma 800 ePTFE – Expanded PTFE sheet material with enhanced low stress sealing characteristics and improved blow-out resistance and is suitable for sealing most chemicals across the pH range.

- FDA compliant seals/gaskets

- Gasket/Seals for chemical, pharmaceutical, food

- Gasket/Seals for cryogenic applications

- Reactor Seals/Gaskets

- Gasket/Seals for GFK Flange

- Teflon Seals/Gaskets

Joint Integrity Services

Our team of application engineers understand that the use of high quality seals/gaskets are not a guarantee of sealing success. As a result, Flexitallic application engineering offer a range of Joint Integrity and Technical Services that are designed to complement and enhance Flexitallic’s product offering.

Allowing customers to operate their plants, complete projects and start up from turnarounds safely and efficiently. Our goal is to help customers achieve leak free start-up and operation within the scheduled maintenance cycle.

- Shutdown support

- 13555 Sealing material characteristic values

- EN 1591 calculation for gaskets

- Gasket installation training – 1591-4

- Gaskets to VDI 2290, VDI 2240, TA Luft

- Gasket assembly support

- Application consulting and design

- Research and Development Lab (R&D)

- AMTEC Test benches

- AMTEC High Temperature testing

Contact Us

Flexitallic GmbH

Halkestr. 13

47877 Willich-Münchheide

Germany

T: +49 (0) 2154 95363-0

F: +49 (0) 2154 95363-29

E: customerservice@flexitallic.de